RVA SERVICES

Front-end Engineering Design

As with most undertakings, the quality of inputs in the earliest stages of a decommissioning project will usually dictate the level of success that can be achieved.

RVA therefore recognises that detailed research, planning and the bringing together of competent resources are all factors that will impact on the eventual project outcome. Our front-end engineering services are therefore the foundation stones on which safe and secure projects are built.

Professional engineers and technical advisers

We work exclusively for site owners and operators, completely independently of the supply chain. This means that our professional engineering expertise can be wholly relied upon, whether clients have a single technical query or require extensive advice to support the robust execution of any future decommissioning works.

Unlike a client’s own in-house resource, we always approach projects with a decommissioning-first mindset, which means we strive to complement the skills and knowledge of existing personnel, to help deliver safe, commercially-secure and environmentally sound outcomes, however straightforward or complex the brief.

Methodology design statutory duty holder

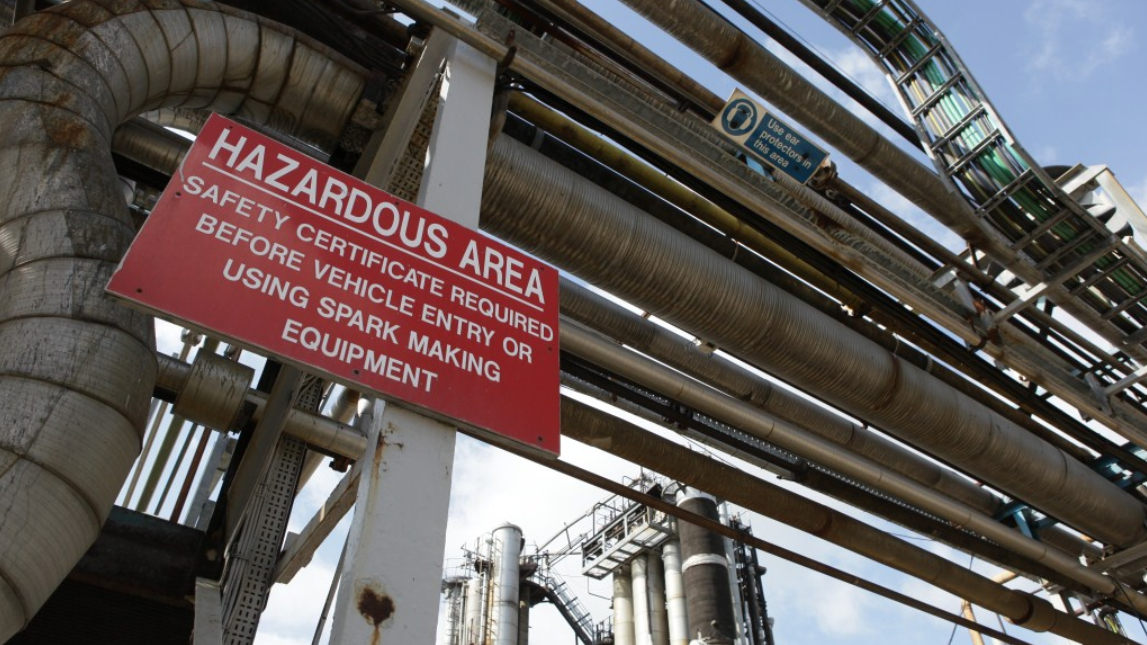

When designing decommissioning and demolition methodology, it is the statutory duty holder’s role to help manage safety standards on these potentially high-hazard assignments. We analyse varied risks – relating to the industrial background of the site, the operational status of plant and the decommissioning discipline itself – often with the input of a client’s personnel. The objective is to then understand how they interact with one another, so that direction can be provided to help mitigate the danger they pose.

Often a legal requirement, governed by rules such as the Construction Design Management (CDM) regulations in the UK, the appointment of a Principal Designer (PD) or other statutory duty holder also ensures the integrity of good practice and project management structure at every stage. RVA adopts this role for the majority of clients.

Decommissioning and demolition cost assessments

It usually helps to have a decommissioning project cost indication as soon as possible. This information can then be used to compile sanction grade estimates, funding applications and even determine the project programme and duration – not to mention financial milestones to support ongoing cost control when works are underway.

When undertaking these evidenced cost assessments, direct costs such as contractor fees will be evaluated alongside wider factors including the potential plant resale value, market conditions and the possible effect of legislative changes, for example.

Structural assessments and surveys for demolition and dismantling

These thorough assessments typically investigate the condition and stability of site assets before providing technical advice and costings for the decommissioning, demolition and dismantling that may follow. The outcomes of these surveys often help to determine the shape, timescales and urgency of onward project roadmaps, based on evidenced findings as opposed to presumptions.

The role of a costings study in decommissioning

It is often considered one of the least ‘hands on’ elements of a decommissioning project, but the execution of a costings study is in fact one of the most crucial and sophisticated uses of engineering acumen, when it comes to securing a safe, commercially and environmentally-sound project outcome. RVA Group was interviewed by Tanks and Terminals magazine on this very topic…

Physical, virtual or hybrid decommissioning support

When it comes to our provision of decommissioning services, we can adopt varied deployment methods, including a physical on-site presence, virtual support, or a hybrid approach. Exactly what is feasible will depend on the scope of work involved, and decisions will always be made on the grounds of safety. However, where possible we will actively seek to make best use of technology and remote or geographically diverse resources, to reduce the unnecessary carbon impact of travel, and keep programmes progressing fluidly whatever else may be going on in the world.